Cold rolled steel sheet parts are prone to deformation during the production process due to external forces, which can lead to inaccurate dimensions of the parts and affect their reliability and durability. To solve this problem, a precision leveling machine can be used for rapid leveling.

Precision leveling machine is a high-precision machine specifically designed to remove internal stress in metal workpieces, which can restore the workpiece to its original shape by applying pressure. It has the characteristics of high precision, high efficiency, and high stability, and can quickly and accurately level cold rolled steel plate parts.

When using a precision leveling machine for leveling, the following points need to be noted:

1. Ensure that the pressure adjustment of the leveling machine is reasonable to avoid the impact of excessive pressure on cold rolled steel plate parts.

2. Select appropriate leveling processes and equipment based on the size, shape, and deformation of cold rolled steel plate parts to ensure that the leveling effect meets expectations.

When leveling cold rolled steel plate parts, multiple cycles are required to ensure that the shape and flatness of the parts meet the requirements.

In summary, precision leveling machines are a very effective tool that can be used to level metal products such as cold-rolled steel plate parts. By using precision leveling machines correctly, the quality and stability of parts can be improved, ensuring that cold rolled steel plate parts meet the requirements.

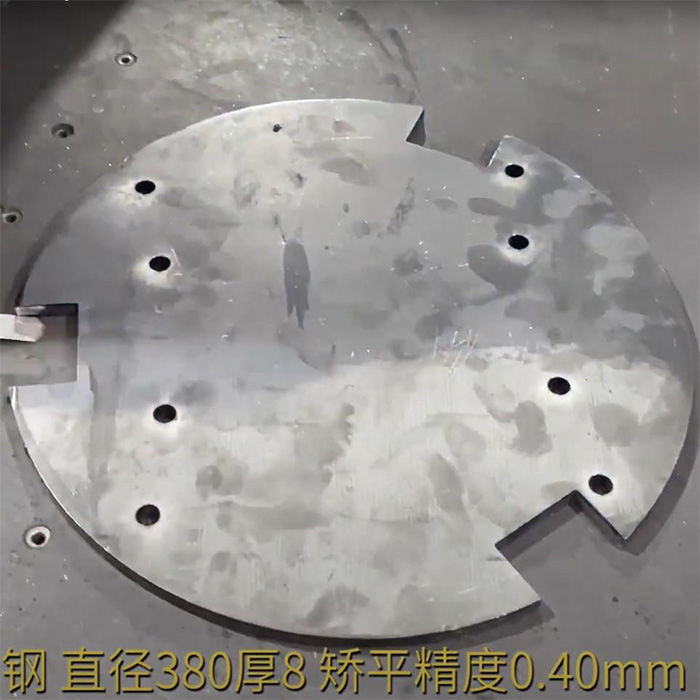

| Materials | Length | Width | Thickness | Accuracy |

| Steel | 380mm | 380mm | 8mm | 0.2mm |

Watch Video: