A warped aluminum alloy refers to a material that undergoes warping deformation during force or deformation. This deformation is usually caused by uneven stress inside the material, resulting in excessive stress in certain areas of the aluminum alloy material and distortion deformation.

During the manufacturing process of aluminum alloy materials, uneven heating or cooling, or improper processing force may cause warping and deformation of the aluminum alloy material. In addition, if the composition, temperature, humidity, hardness and other parameters of aluminum alloy materials are not suitable, it may also lead to warping deformation of aluminum alloy materials.

To avoid the warping deformation of aluminum alloy materials, it is necessary to strictly control the composition and processing parameters of the material during the material manufacturing and processing process, to ensure the uniformity and stability of the material. In addition, when using aluminum alloy materials, it is also necessary to avoid excessive stress or deformation to reduce the risk of warping deformation.

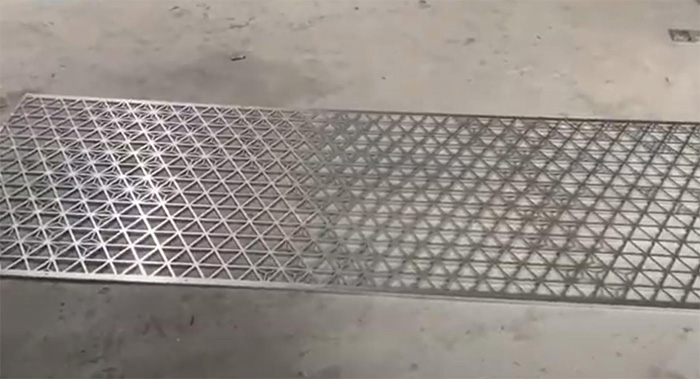

In order to solve the problem of plate warping, leveling treatment is required. Leveling is a method of restoring a flat state of a sheet metal by stretching and compressing it through mechanical and thermal forces. During the leveling process, the sheet metal is sandwiched between two large leveling rollers. Through the rotation and pressure of the rollers, the sheet metal is deformed, internal stress is removed, and finally a flat sheet metal is obtained.

Leveling treatment can effectively solve the problem of plate warping, improve the flatness and stability of the plate, and make it meet quality standards. At the same time, leveling can also improve the surface quality of the board, enhance its machinability and service life.

In short, the board is prone to warping during manufacturing and transportation, which affects the quality and stability of the product. To solve this problem, it is necessary to carry out leveling treatment to restore the sheet to a flat state and meet quality standards. Leveling treatment is an important process, and only after strict leveling treatment can high-quality products be guaranteed to be produced.

| Materials | Length | Width | Thickness | Accuracy |

| Aluminium alloy | 4000mm | 900mm | 5mm | 0.3mm |