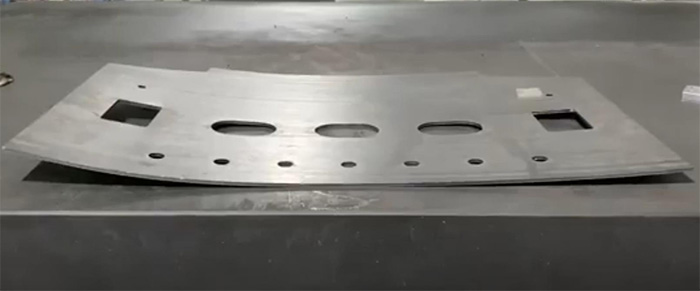

In the process of laser cutting, a high-energy density laser beam will locally heat and melt the workpiece, and then use a gas flow to blow away the melted material, thereby achieving cutting. However, due to the high temperature and thermal stress generated during laser cutting, many workpieces undergo deformation after cutting, which affects their accuracy and quality. To solve this problem, the workpiece needs to be leveled again.

Leveling again is a method of restoring the workpiece to a flat state through mechanical force. During the leveling process, the workpiece is sandwiched between two large leveling rollers. Through the rotation and pressure of the rollers, the workpiece is deformed, internal stress is removed, and finally a flat workpiece is obtained. By using this processing method, the problem of workpiece deformation can be eliminated, making it meet the processing requirements.

After laser cutting, there are many types of deformation of the workpiece, including bending, warping, twisting, etc. Different leveling methods are required for different deformation situations. For example, for bent workpieces, cold bending leveling can be used; For warped workpieces, thermal leveling can be used; For twisted workpieces, mechanical leveling can be used.

In short, after laser cutting, many workpieces will undergo deformation, which affects their accuracy and quality. To solve this problem, the workpiece needs to be leveled again. Leveling again is an effective method that can eliminate the problem of workpiece deformation and make it meet the machining requirements.

| Materials | Length | Width | Thickness | Accuracy |

| Cold-rolled sheet | 1030mm | 750mm | 5mm | 0.1mm |

Watch Video