Metal parts undergo deformation due to the release of internal stress after heat treatment, and require leveling by a leveling machine.

During the heat treatment process of metal materials, internal stress may occur due to temperature changes and structural changes. These stresses can cause deformation and unevenness of metal parts, affecting their accuracy and quality. To solve this problem, it is necessary to use a leveling machine to level the metal parts.

Leveling machine is a mechanical equipment that removes internal stress and restores flatness by stretching, compressing, and other processing on metal materials, achieving accuracy requirements. Commonly used leveling machines include flat plate leveling machines, roller leveling machines, bending leveling machines, etc.

After heat treatment of metal parts, it is necessary to place them for a period of time to let them Free cooling in order to release internal stress. Then, use a leveling machine to level it and restore its flatness. This can ensure the accuracy and quality of metal parts, improve their service life and stability.

It should be noted that different metal materials and heat treatment processes correspond to different leveling machines and leveling processes, which need to be selected based on actual situations. At the same time, the operation of the leveling machine requires professional skills and experience, and attention should be paid to safe operation.

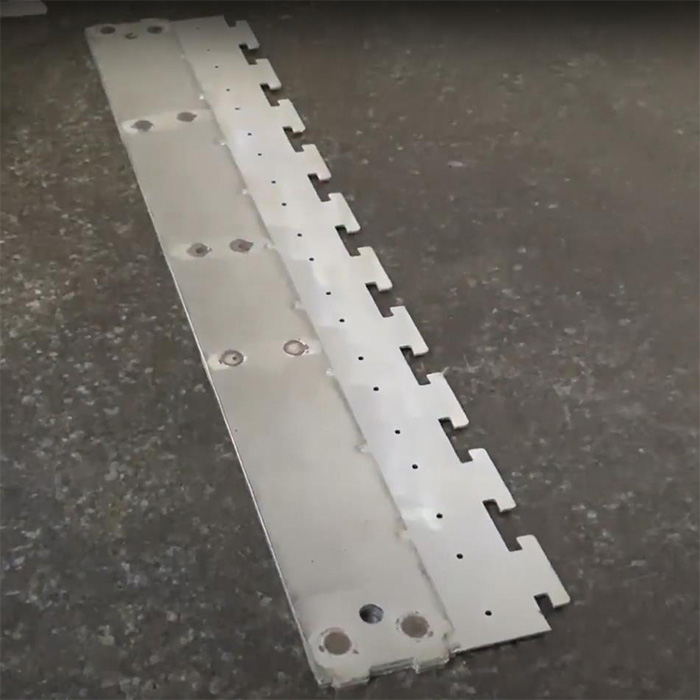

| Materials | Length | Width | Thickness | Accuracy |

| Steel | 460mm | 100mm | 6mm | 0.1mm |