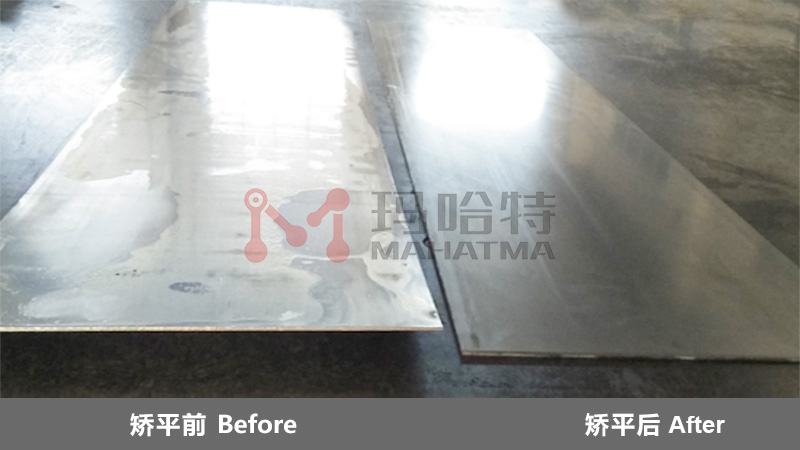

Galvanized sheet refers to a steel sheet plated with a layer of zinc on the surface. Galvanizing is a frequently used economical and effective method of rust prevention, and about half of the world's zinc production is used in this process. And how to ensure the plane accuracy of galvanized sheet? Can the flatness error be less than 0.1mm after using the leveling machine?

During the leveling process of the leveling machine roll, the metal sheet is subjected to a series of alternating bending, and the motor and PLC control the precise control of the pressing amount of each leveling roller to eliminate internal stress and fundamentally solve the problem of sheet metal. The leveling effect is not ideal due to the different stress of each part, so as to achieve high-precision leveling. The plane accuracy error can reach 0.01mm-0.1mm. It is the best choice for solving high-precision machine accessories!

Hot and cold rolled - how sheet metal is produced

There are several common sheet metal manufacturing processes on the market. The original product is usually composed of rectangular cast steel blocks, called slabs. These slabs are rolled to the required thickness by reversible or continuous hot rolling process in the steel plant or rolling mill. In the continuous production process, slabs are rolled to the required thickness through a series of connected rolling mills, and the length of finished products can reach hundreds of meters. The slab is then cut to a predetermined length or rolled into coils. Another method is to roll the plate to the corresponding thickness through the continuous back and forth movement of the roller. This method is applicable to plates with a thickness of 5 mm or more and a width of 2000 mm or more. The rolling thickness of these two processes will overlap in a certain range. With hot rolling process, some sheet metal can be produced continuously or by reverse technology.