Sheet metal parts have different shapes and thicknesses in different application fields. Each sheet metal needs an accurate and fixed shape to ensure that it can reliably pass through various downstream production processes. It needs to be suitable for various fault-free, repeatable and efficient manufacturing. In this case, the leveling process plays a particularly important role in the sheet metal processing process.

Find the correct internal stress

Each plate has its internal stress, which affects the quality and reliability of subsequent manufacturing processes. However, they are often difficult to measure, and generally only appear through the unevenness or deformation of the plate surface. Sometimes it is not easy to be seen by the naked eye, and its disadvantages will be highlighted only when welding, milling or bending. And it is often difficult to determine how much residual stress remains in the leveled plate.

Therefore, for some decision makers, it is not easy to evaluate the actual benefits of leveling plates. Generally speaking, the smaller the internal stress of the plate, the more barrier free and efficient the manufacturing. For example, the welder will exclaim when processing materials: the leveled plate is not only flat and easy to operate, but also greatly reduces the assembly time. Secondly, the dimensions are more accurate during assembly and no rework is required. This result is helpful to the formulation of production quality and production plan. For decision makers, the benefits of these leveling will also be reflected in the saving of production costs.

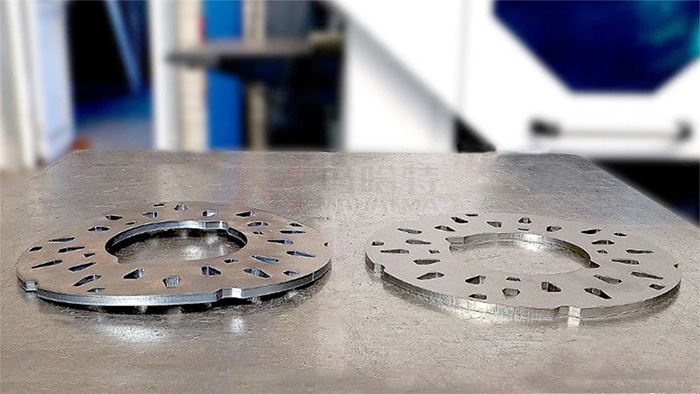

In addition to the internal stress of the plate itself, stress and uneven areas will also occur during the manufacturing process. Just like laser or plasma thermal cutting, a large amount of heat will be generated at the cutting edge, forming a temperature gradient and causing stress. It also stiffens the edges. As a result, the parts are deformed, which hinders effective downstream processing. At this point, the only way to solve this problem is leveling.