With the development of the manufacturing industry, stamping products are becoming increasingly refined and complex. Products with complex shapes require multiple processes, and a set of continuous molds is required in mold manufacturing to complete the entire stamping task. Continuous molds require continuous feeding of materials. Traditional stamping production often uses manual feeding to the punching machine, which requires manual feeding, feeding, and adjusting the step distance. The entire process requires two people, one to feed and the other to control the punching machine. The labor intensity of workers is high, the efficiency is low, the cost is high, and the feeding speed is unstable, directly affecting the quality of stamping products.

Servo feeder is a device commonly used on coil cutting lines, which provides precise coil feeding control through a servo system. It is driven by high-precision servo motors and can achieve fast and accurate coil feeding. This equipment has the characteristics of high speed and precision, which can accurately control the feeding length and speed of the coil, improve production efficiency and product quality. At the same time, the servo feeder also has automatic detection and correction functions, which can automatically adjust the position of the coil to ensure the accuracy of cutting.

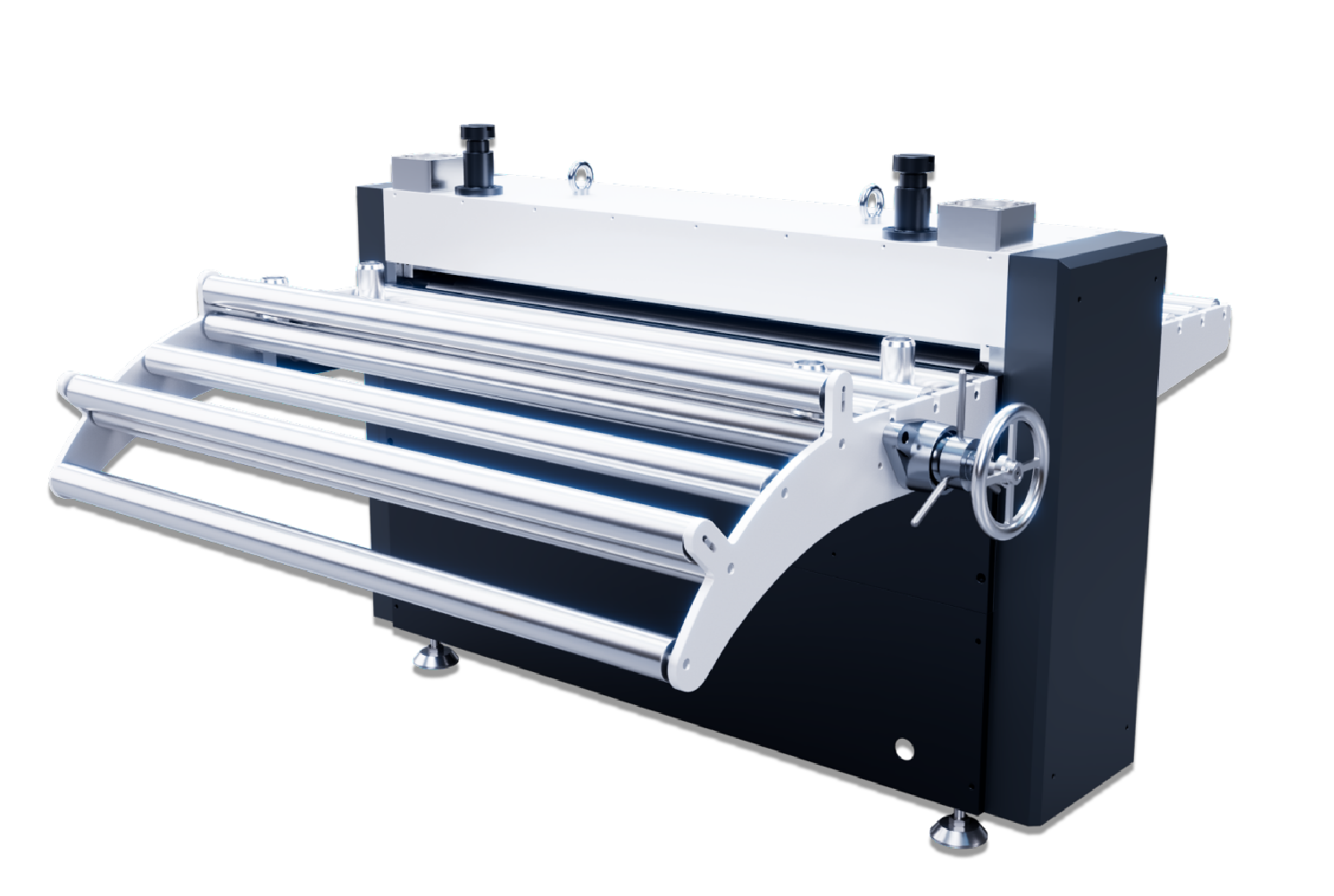

The roller feeder is currently the most cost-effective automatic feeding equipment in the stamping industry to replace manual feeding. It is suitable for automatic feeders for 0-3.0mm material stamping. The feeding accuracy is ±0.05mm. If the guide pin is positioned, it can be ±0.01 mm accuracy. The power of the roller feeder comes from the output shaft of the punch itself. When the punch is working, the output shaft is driven to rotate. The punch goes up and down once, and the output shaft rotates once. The eccentric disk of the roller feeder is installed on the output shaft through a fixed seat. An adjustable pull rod is connected to the lower part of the eccentric disk. The adjustable pull rod is connected to the rocker arm of the roller feeder through a cross joint. The eccentric disk rotates once and the rocker arm swings up and down once. The swing distance of the rocker arm is determined by the radius of the adjustable tie rod, which is adjusted according to the step distance of the mold. Fixedly connected to the rocker arm is the transmission shaft, which rotates left and right as the rocker arm swings up and down. One end of the feeding drum of the roller feeder is connected to the transmission shaft, which drives the feeding drum to rotate. The relative movement between the upper and lower feeding drums drives the material to be processed forward to achieve the purpose of feeding.