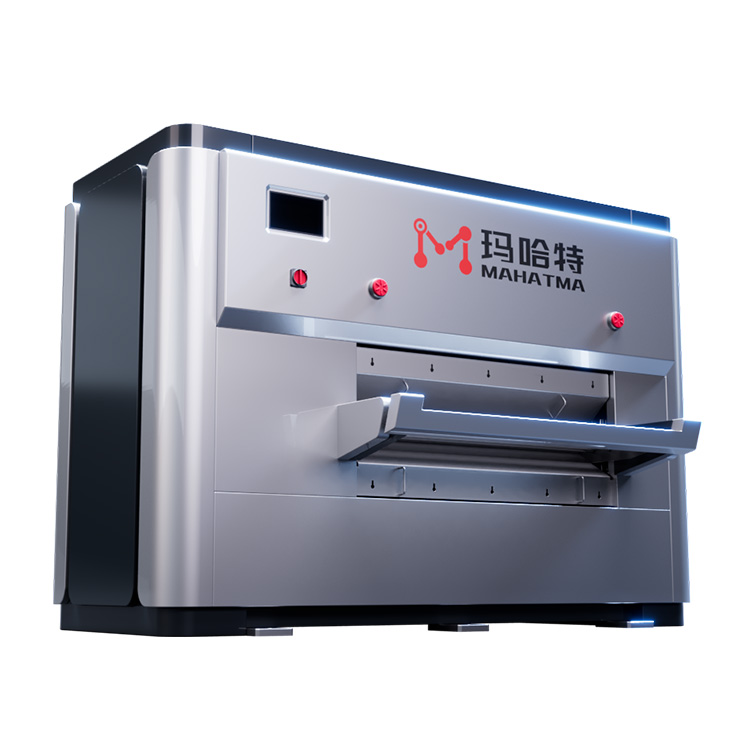

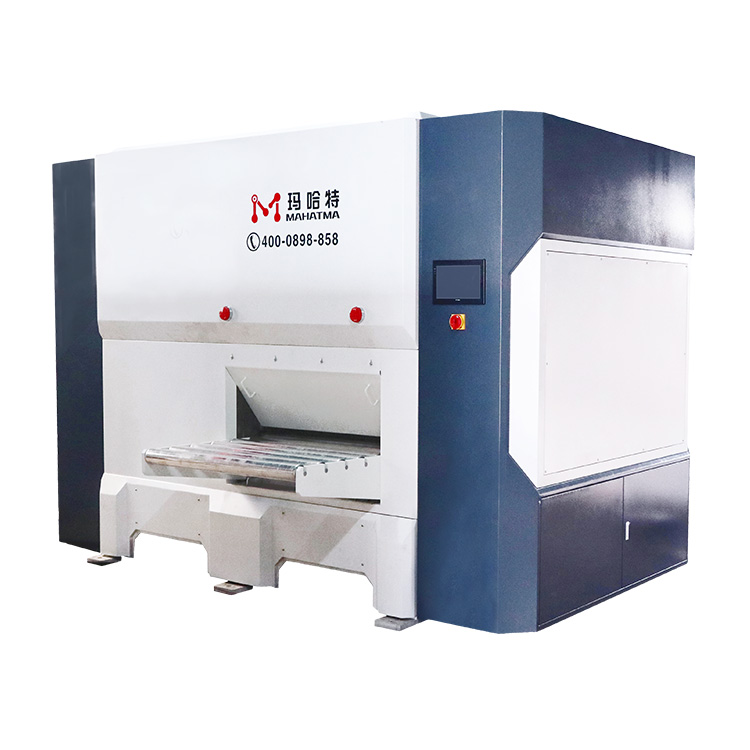

Sheet metal flattening machines are essential tools for the manufacturing industry. They are used to flatten and straighten sheet metal, which is a commonly used material in the production of various products. The machine is designed to take a sheet of metal and flatten it to a specific thickness. The process of flattening sheet metal is critical in the manufacturing industry, as it ensures that the material is uniform in thickness, making it easier to work with.

Sheet metal flattening machines come in different models and sizes. The choice of a machine depends on the size of the sheet metal to be flattened and the type of material being used. The most common types of sheet metal flattening machines are hydraulic press machines, mechanical press machines, and pneumatic machines. Each of these machines has its unique features and advantages.

Hydraulic press machines are popular in the industry because they are easy to operate and can be used to flatten large sheets of metal. They use hydraulic pressure to flatten the metal, and the pressure can be adjusted to achieve the desired thickness. Hydraulic press machines are ideal for use in the production of large items, such as car body parts, as they can flatten sheets of metal up to several meters in length.

Mechanical press machines, on the other hand, use a mechanical force to flatten sheet metal. They are relatively cheaper than hydraulic press machines, and they are suitable for use in the production of smaller items. Mechanical press machines are also easy to operate, and they have a high production rate.

Pneumatic sheet metal flattening machines use compressed air to flatten sheet metal. They are lightweight and portable, making them ideal for use in small workshops or for onsite repairs. Pneumatic machines are also ideal for use in the production of small items, such as electronic components.

Sheet metal flattening machines are essential in the manufacturing industry, as they ensure that the sheet metal is uniform in thickness and free from deformities. They are used in the production of various products, including car body parts, electronic components, and household appliances.

The process of flattening sheet metal involves several stages. The first stage is the preparation of the sheet metal. The sheet metal is cleaned of any rust or dirt, and any deformities are removed. The sheet metal is then cut to the desired size and shape.

The second stage is the flattening of the sheet metal. The sheet metal is placed on the flattening machine, and pressure is applied to flatten the metal to the desired thickness. The thickness of the sheet metal is critical in the production of various products, as it affects the strength and durability of the final product.

The third stage is the finishing of the sheet metal. The flattened sheet metal is polished to remove any scratches or marks, and it is checked for any deformities. The sheet metal is then ready for use in the production of various products.

Sheet metal flattening machines are essential in the manufacturing industry, as they ensure that the sheet metal is uniform in thickness and free from deformities. They are used in the production of various products, including car body parts, electronic components, and household appliances.

The choice of a sheet metal flattening machine depends on the size of the sheet metal to be flattened and the type of material being used. Hydraulic press machines are ideal for use in the production of large items, while mechanical press machines are suitable for use in the production of smaller items. Pneumatic machines are ideal for use in small workshops or for onsite repairs.

In conclusion, sheet metal flattening machines are essential tools in the manufacturing industry. They are used to flatten and straighten sheet metal, ensuring that the material is uniform in thickness and free from deformities. The choice of a machine depends on the size of the sheet metal to be flattened and the type of material being used. Hydraulic press machines, mechanical press machines, and pneumatic machines are the most common types of sheet metal flattening machines used in the industry.