Menu

- Home

- Products

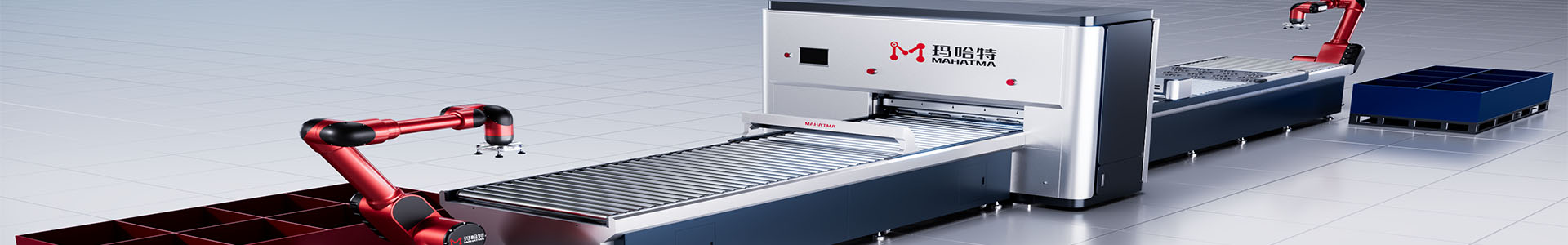

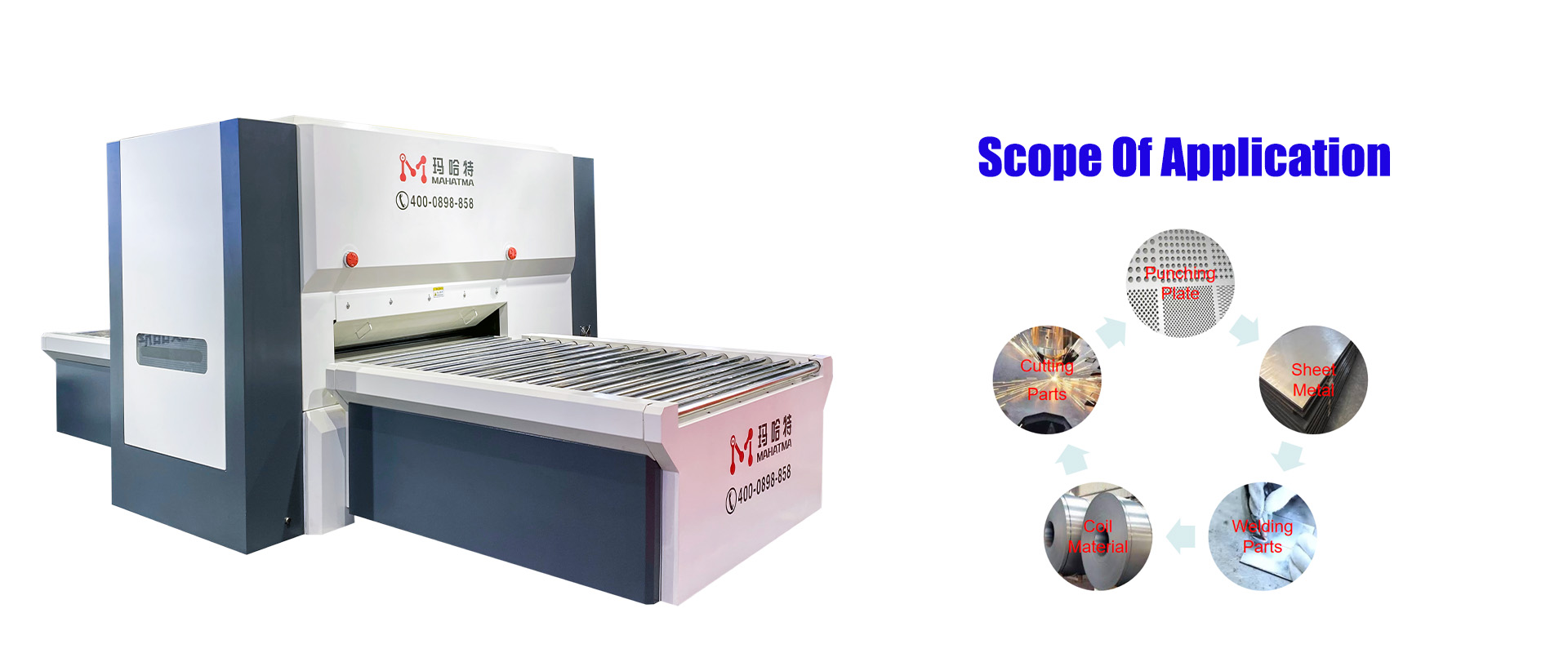

- Sheet Metal Leveling Machine

- Sheet Metal Flattening Machine

- Sheet Metal Straightening Machine

- Semi-Automatic Leveling Machine

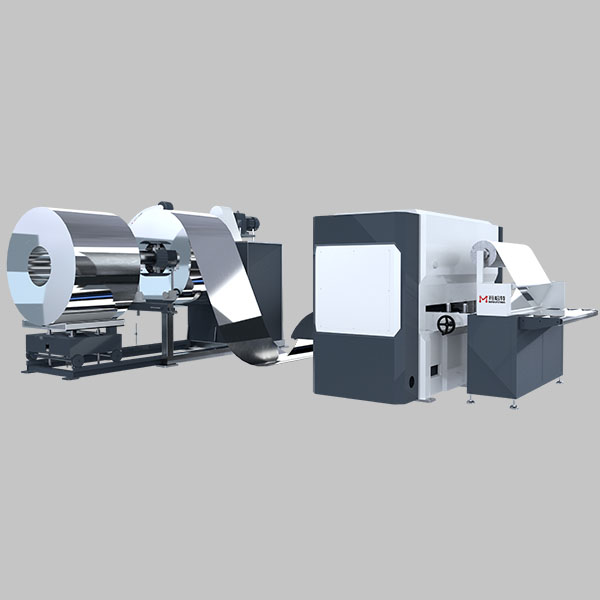

- Cut to length

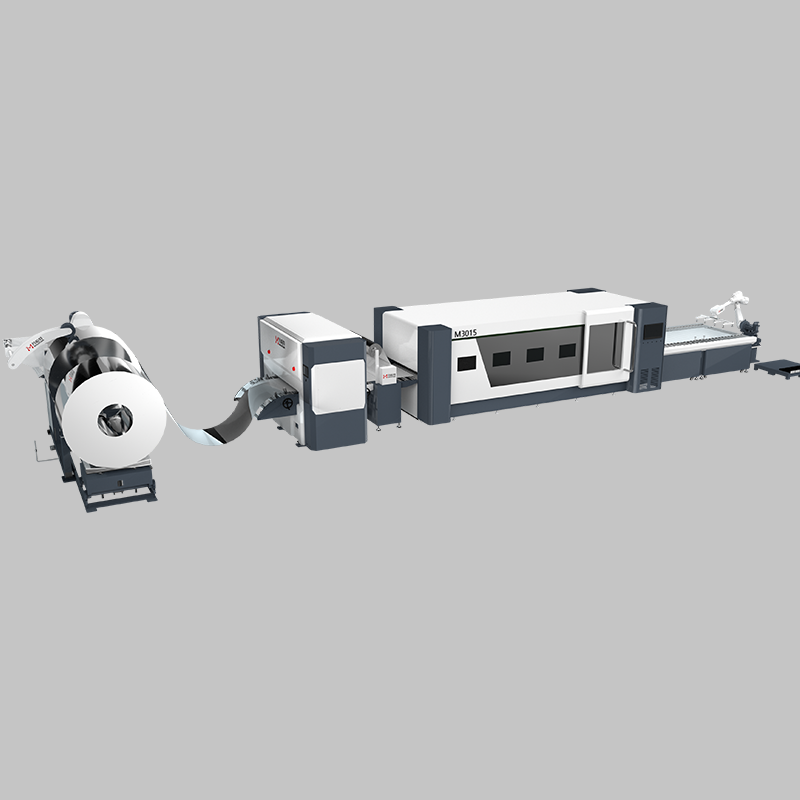

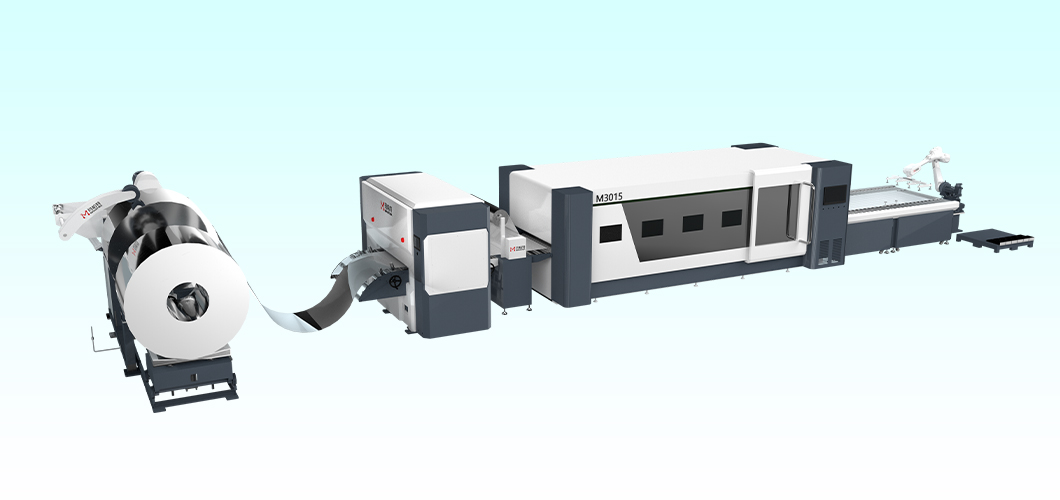

- Laser Cutting Blanking

- Videos

- Sheet Metal Leveling Machine

- Sheet Metal Flattening Machine

- Sheet metal straightening machine

- Semi-automatic leveling machine

- MAHATMA Factory

- Case

- Sheet Metal Leveling Machine

- Sheet Metal Flattening Machine

- Sheet metal straightening machine

- Semi-automatic leveling machine

- News

- Company News

- Product News

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

- Factroy

- Contact Us

Search